- Description

Description

Cobot Automation Manufacturer In Malaysia

Innovative Robotics Technology at Your Fingertips. The GigaArm-2 is a cutting-edge robotic arm designed for versatility and precision. From its robust base to its dexterous gripper, the GigaArm-2 is built to handle a variety of tasks. Its sleek design and advanced capabilities demonstrate a commitment to innovation.This robotic arm is poised to become a valuable tool for businesses seeking to improve efficiency and productivity.

Our collaborative robot (cobot) solutions provide affordable and intelligent automation for businesses looking to improve productivity, reduce labor dependency, and enhance operational efficiency. Designed to work safely alongside human workers, our cobots help solve the growing shortage of low-skilled labor in manufacturing, logistics, and service industries.

We specialize in delivering cost-effective cobot systems that are easy to deploy, simple to operate, and flexible enough to integrate into existing production lines and facilities. By retrofitting into current workflows, our automation solutions allow companies to adopt Industry 4.0 technology with minimal investment and fast implementation.

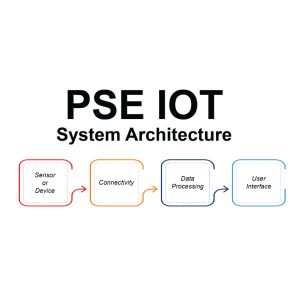

With advanced IoT connectivity, autonomous robotics, and enterprise software integration, our cobots enable real-time data collection, process monitoring, and smarter decision-making. This levels the playing field for businesses of all sizes by making Big Data and automation accessible even to small and medium enterprises.

Our goal is to help organizations increase ROI by boosting productivity while reducing labor costs and operational inefficiencies. From repetitive assembly and packaging tasks to material handling and inspection, our collaborative robots improve consistency, speed, and workplace safety.

Whether you are a growing business or an established manufacturer, our cobot automation systems provide scalable, future-ready solutions that enhance competitiveness, optimize performance, and accelerate digital transformation.

The modular structure of this material handling system provides flexibility and enables customization to suit a wide range of production requirements. Its curved conveyor belts showcase the system’s capability to handle complex layouts and integrate smoothly with existing facilities. This versatility makes it an important tool for businesses aiming to enhance material flow and quickly adapt to evolving operational demands.

This robotic palletizing system demonstrates the power of automation in modern warehousing and manufacturing. The robotic arm efficiently handles and stacks bags of material onto pallets, optimizing workflow and reducing manual labor. This automated solution increases throughput, minimizes errors, and improves overall productivity.

The integration of PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) technologies offers a robust solution for process automation. The PLC manages the fundamental control tasks, while the HMI system delivers an intuitive interface for monitoring and supervision. Together, they boost efficiency, minimize human error, and strengthen overall process control.

The integration of PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) technologies offers a robust solution for process automation. The PLC manages the fundamental control tasks, while the HMI system delivers an intuitive interface for monitoring and supervision. Together, they boost efficiency, minimize human error, and strengthen overall process control.

Key Benefits

✅Economical & Practical

- Cheapest & fastest delivery IR4.0 IoT solutions in Malaysia which tailored for Malaysia industry especially for SME.

✅Plug & Play Deployment

- Connect and configure without code.

✅USP: Dip-switch based

- integration in minutes (no coding)

✅No Coding Required

- Anyone can integrate devices with ease

✅API Communication Ready

- Allows seamless integration with external system & 3rd party platforms.

✅Instant Integration

- IT engineers or client-side developers can connect their own cloud system to front-end IoT nodes or sensors within minutes.

✅Rapid Time to Value

- Digitalize your system in just minutes

✅Universal Compatibility

- Works with new or legacy industrial hardware

✅Support multiple industrial signals

- : Analog, digital, pulse

✅Cost- Efficient

- worlds cheapest IoT module & platform, while cutting down on expensive engineering hours.

- Seamless cloud integration with PSE Cloud platform

Open architecture to seamlessly integrate with a wide range of enterprise system (the Power of API communication Ready)

Up to date, with PSE standard cloud to cloud protocol (API Ready), we had successfully deployed numerous IR 4.0 projects (shortest timeframe than usual) and integrated with different kinds of software system including PLC System, Material Resource Planning-II(MPRII),

Manufacturing execution system (MES), Inventory Control System, Warehouse Management System (WMS), WIP Process by Bar Coding System, Barcoding/RFID System and more to be come. These Smart manufacturing solutions are widely accepted/installed throughout Malaysia.

Why Choose Our 4.0 Technology?

✅ 100% research, design & developed by Malaysia, over 85% of components sourced locally in Malaysia.

✅ Working closely with Malaysian developers like, Sirim Berhad and Koon Seng Sdn Bhd of companies on delivered all the IR4.0 related projects in Malaysia which involving full system integration of IoT, automation, robotic, PLC, ERP and RFID

✅ Together, we are shaping brighter & better industry future for our nation.

Why Choose PSE Machinery?

- ✅ Local design & manufacturing in Melaka

- ✅ Delivery & technician team support across Malaysia

- ✅ Customizable

📞 Get a Free Quote

Need a cobot automation collaborative robots in Malaysia? Contact PSE Machinery today!

- 📞 Phone: 016-667 7148 / 012-607 9928

- 📍 Showroom: Melaka, Malaysia