- Description

Description

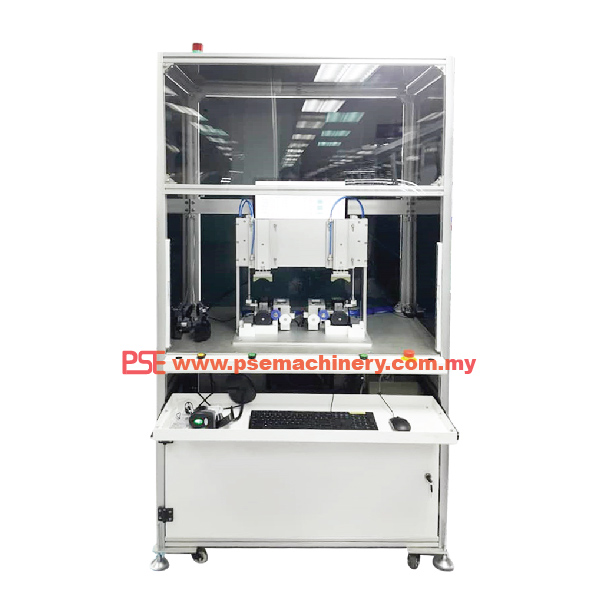

Our Cobot Vision Pick & Place solution combines collaborative robotics with advanced vision technology to deliver fast, accurate, and flexible automation for modern production lines. Equipped with intelligent camera systems, the cobot can automatically identify, locate, and pick products from conveyors, trays, or random positions, then place them precisely into the next process stage.

This system is ideal for tasks such as sorting, packaging, assembly, and quality handling, helping manufacturers improve productivity while maintaining consistent accuracy. With safe human-robot collaboration, the cobot can operate alongside workers without complex safety barriers, making it perfect for SMEs and smart factory environments.

Key Benefits:

-

High-precision vision-guided picking

-

Flexible handling of different product shapes and sizes

-

Reduced manual labor and increased efficiency

-

Easy integration into existing production lines

-

Safe and collaborative operation

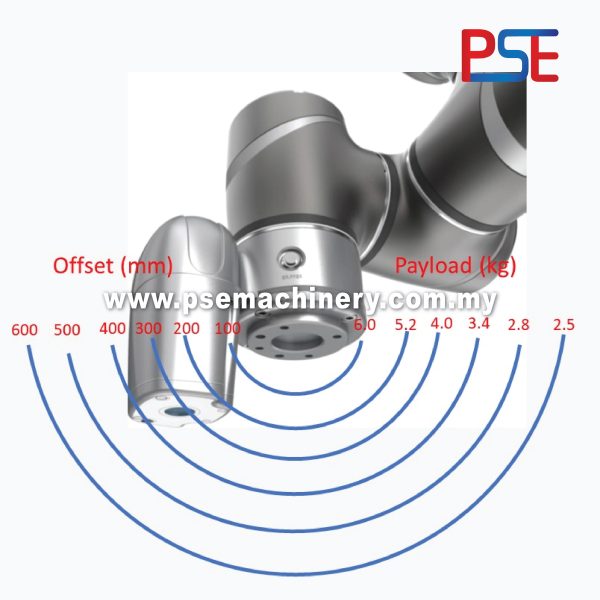

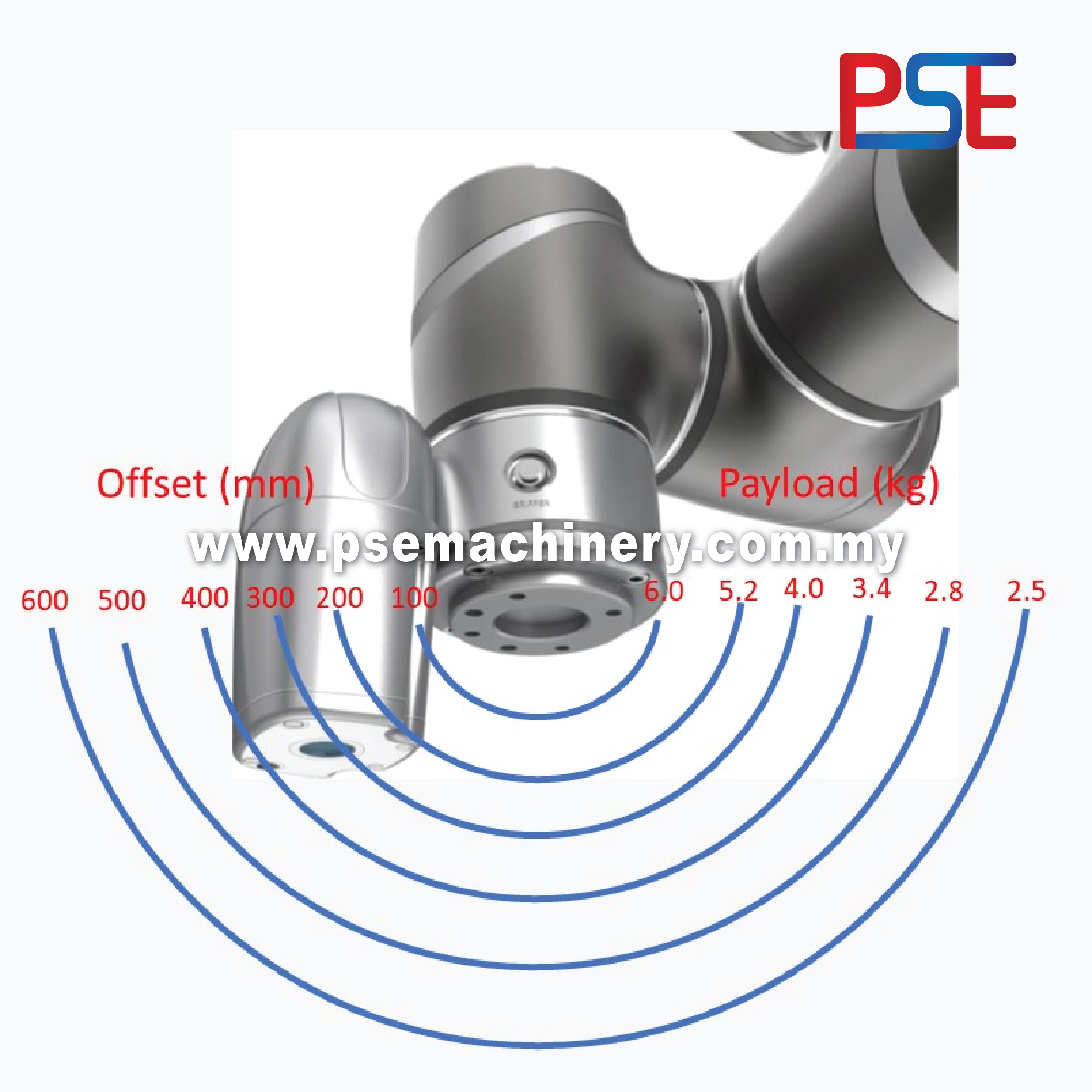

- Example if the robot end and the payload (the black tray) center of gravity is 300mm, then maximum it can carry is 4kg

Upgrade your factory with a smarter, faster, and more reliable pick & place automation solution.

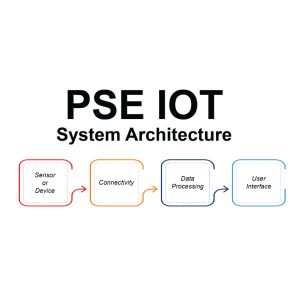

Why Choose Our 4.0 Technology?

✅ 100% research, design & developed by Malaysia, over 85% of components sourced locally in Malaysia.

✅ Working closely with Malaysian developers like, Sirim Berhad and Koon Seng Sdn Bhd of companies on delivered all the IR4.0 related projects in Malaysia which involving full system integration of IoT, automation, robotic, PLC, ERP and RFID

✅ Together, we are shaping brighter & better industry future for our nation.

Why Choose PSE Machinery?

- ✅ Local design & manufacturing in Melaka

- ✅ Delivery & service support across Malaysia

- ✅ Customizable to bottle sizes

📞 Get a Free Quote

Need a packing machine in Malaysia? Contact PSE Machinery today!

- 📞 Phone: 016-667 7148 / 012-607 9928

- 📍 Showroom: Melaka, Malaysia