- Description

Description

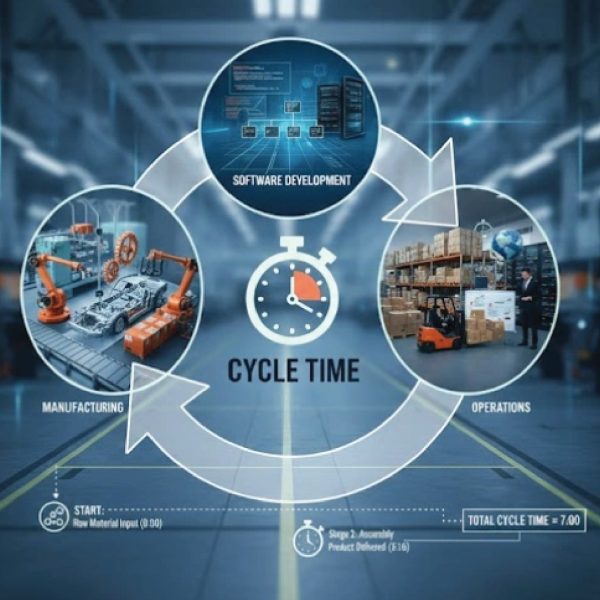

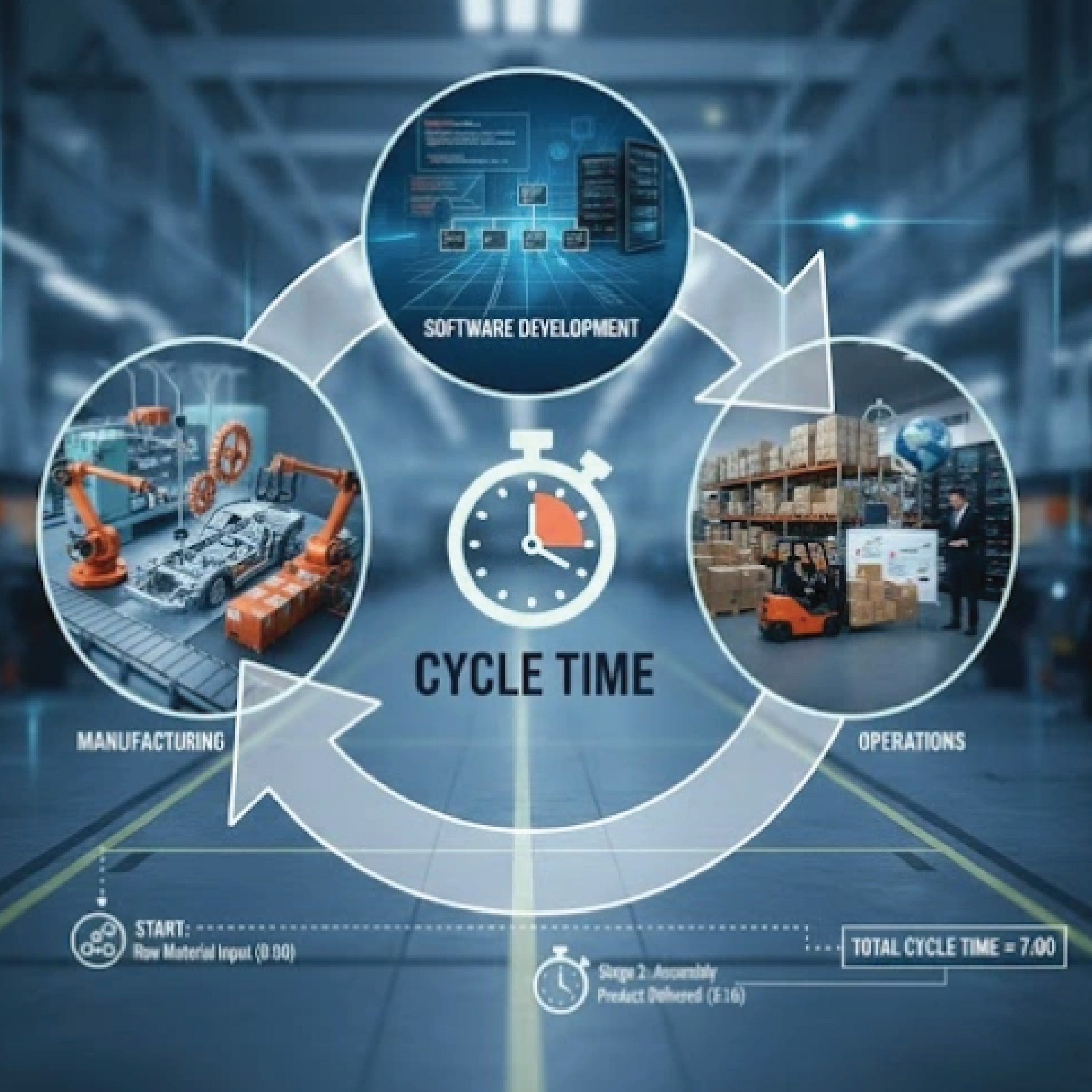

Cycle Time, Time Analysis, and Productivity Monitoring

📂 Project: CycleTime Optimizer 4.0

🔧 Project Concept

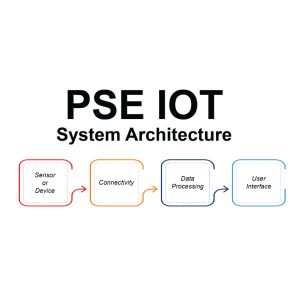

CycleTime Optimizer 4.0 is a smart factory initiative that uses IoT sensors, PLC integration, and cloud analytics to measure and improve cycle time across critical production processes. The goal is to maximize throughput while maintaining quality.

⚙️ Project Scope

– Process Monitored:

– Packaging Line for bottled beverages.

– Each cycle = pick bottle → fill → cap → label → pack.

– Data Collection:

– PLC records start/end timestamps for each cycle.

– IoT sensors track conveyor speed, filler RPM, and reject counts.

– Analytics:

– Cloud dashboard calculates average cycle time per unit.

– Trend analysis highlights bottlenecks (e.g., labeling slower than filling).

– AI suggests adjustments (increase conveyor speed, optimize filler timing).

– Optimization Actions:

– Reduce cycle time from 12 seconds/unit → 9 seconds/unit.

– Increase productivity by 25% output per hour.

– Reject rate reduced by 15% due to stable cycle consistency.

The automatic packaging machine is equipped with an intelligent monitoring system that analyzes cycle time, operational time, and production output to improve overall productivity. By accurately measuring the time taken for each packaging cycle, the system ensures consistent machine performance and optimal production speed.

The HMI and web-based monitoring platform continuously records key time-related data, including cycle time per unit, total running time, idle time, and downtime duration. This time analysis allows manufacturers to identify inefficiencies, bottlenecks, and performance variations during production.

Production output data, such as total units produced, reject quantity, and output rate per hour, is automatically calculated and stored in a centralized data logger. By correlating time taken with production output, the system provides clear insights into machine productivity and operational efficiency.

With real-time access to cycle time and output analysis through a secure website, production teams can make data-driven decisions to reduce downtime, increase throughput, optimize machine settings, and improve overall manufacturing performance in automatic packaging operations.

Why Choose Our 4.0 Technology?

✅ 100% research, design & developed by Malaysia, over 85% of components sourced locally in Malaysia.

✅ Working closely with Malaysian developers like, Sirim Berhad and Koon Seng Sdn Bhd of companies on delivered all the IR4.0 related projects in Malaysia which involving full system integration of IoT, automation, robotic, PLC, ERP and RFID

✅ Together, we are shaping brighter & better industry future for our nation.

Why Choose PSE Machinery?

- ✅ Local design & manufacturing in Melaka

- ✅ Delivery & service support across Malaysia

- ✅ Customizable to bottle sizes

📞 Get a Free Quote

Need a auto machine in Malaysia? Contact PSE Machinery today!

- 📞 Phone: 016-667 7148 / 012-607 9928

- 📍 Showroom: Melaka, Malaysia