- Description

Description

iMaintain 4.0

-

IoT meters monitor electricity consumption for each machine.

-

Data analysis identifies the machines that consume the most energy.

-

System recommendations suggest an optimal operation schedule.

Project 1 : The tank mixer heater only turns on when the temperature drops below a threshold, instead of running continuously.

🔧 Concept

Energy Management in Industry 4.0 is about monitoring, analyzing, and optimizing energy usage across machines and processes. It ensures that production is not only automated and predictive but also sustainable and cost‑efficient.

⚙️ How It Fits Into Smart Factory 4.0

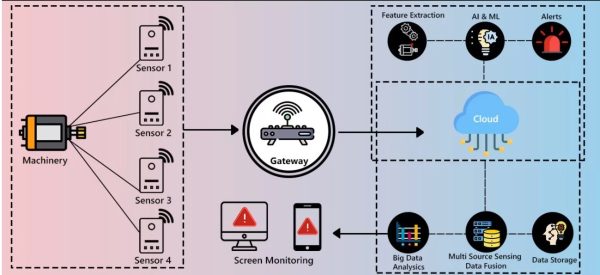

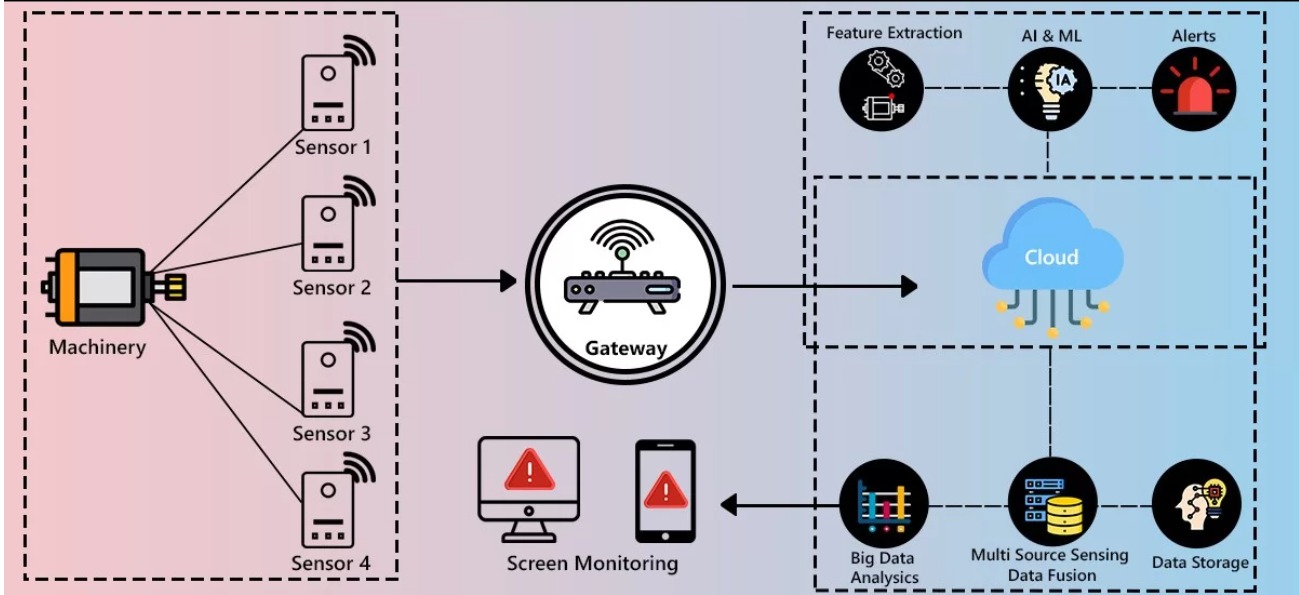

– Integration with IoT & PLCs

– Energy meters and sensors connected to PLCs.

– Data transmitted via Modbus TCP/MQTT into IoT platforms.

– Real-Time Monitoring

– Dashboards show kWh consumption, peak demand, and machine efficiency.

– Operators can see which machines consume the most energy.

– Analytics & Optimization

– Cloud analytics detect inefficiencies (e.g., motors running idle, heaters overheating).

– AI algorithms recommend load balancing, scheduling, or shutdown of unused equipment.

– Predictive Maintenance Link

– Abnormal energy spikes often indicate mechanical wear.

– Energy data supports predictive maintenance decisions.

Why Choose Our 4.0 Technology?

✅ 100% research, design & developed by Malaysia, over 85% of components sourced locally in Malaysia.

✅ Working closely with Malaysian developers like, Sirim Berhad and Koon Seng Sdn Bhd of companies on delivered all the IR4.0 related projects in Malaysia which involving full system integration of IoT, automation, robotic, PLC, ERP and RFID

✅ Together, we are shaping brighter & better industry future for our nation.

Why Choose PSE Machinery?

- ✅ Local design & manufacturing in Melaka

- ✅ Delivery & service support across Malaysia

- ✅ Customizable to bottle sizes

📞 Get a Free Quote

Need a auto machine in Malaysia? Contact PSE Machinery today!

- 📞 Phone: 016-667 7148 / 012-607 9928

- 📍 Showroom: Melaka, Malaysia